MM Kembla partners with Mueller Industries on new Streamline ACR Press Fittings with industry-first design

We are pleased to announce that renowned copper manufacturers MM Kembla & Mueller Industries have combined nearly 200 years of manufacturing experience to bring the Streamline ACR Press Fitting system to Australian and NZ markets, suitable for use with AS1571 Copper Refrigeration Tube.

It’s this combined expertise that makes the Streamline ACR Copper Press Fittings the highest quality, flame-free connection system solution. Utilising T.R.A.P. (Two Ring Advance Press) technology, designed specifically for refrigerant piping systems and backed by a 15 Year manufacturing warranty, IT’S THE SAFEST BET. DOUBLE OR NOTHING.

Streamline ACR Press Fittings are the only press fittings on the market with T.R.A.P Technology, featuring DualSeal Ring Design. Streamline ACR Press Fittings incorporate several thoughtful performance features to provide not only a more reliable fitting but one that is more familiar and intuitive. These advancements have focused on delivering a refrigerant press joining system with greater durability, easier installation, and outstanding leak resistance.

MM Kembla will stock and distribute a range of copper ACR press fittings in diameters ranging from ¼” to 1-1/8” OD compatible with R410A and other commonly used refrigerant gases and oils.

Our Streamline T.R.A.P technology is what sets this system apart from others in the market. By using innovative firsts in the world of flame-free joining for air conditioning and refrigeration piping systems, this technology provides super sealing, leak protection and joint strength like no other.

Using similar patterns and lay lengths as traditional braze copper fittings and backed by a 15-year Manufacturing Warranty, this system provides ease of installation convenience and quality reassurance when using refrigeration press fittings on an air conditioning or refrigeration system installation.

STREAMLINE ACR FEATURES

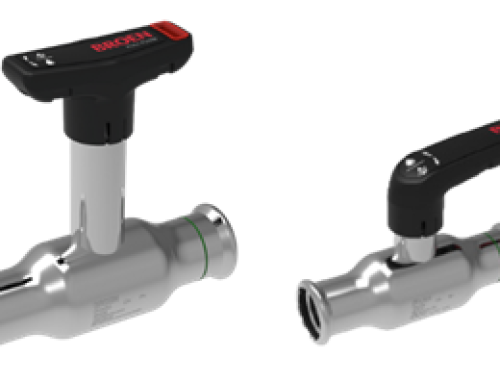

DualSeal Ring Design

- Inspired by Mueller Refrigeration double O-ring valve stem design, Streamline ACR Copper Press Fittings have two specifically engineered HNBR Elastomer sealing O-Rings which operate in tandem to provide 200% more surface contact and sealing area. It is the only press fitting with primary and secondary seals, allowing an improved ability to seal tube imperfections provided by a double protection.

TrapZone Leak Barrier

- As refrigerant molecules are small and notoriously hard to contain, we designed the TRAPZONE LEAK BARRIER to ensure leak protection. How does it work? The precise spacing between the two pressed sealing rings acts as a barrier for refrigerant molecules with the primary seal designed to contain all refrigerant molecules and the secondary seal create a barrier zone for any molecules that may have escaped for greater confidence and reliability. It is the only design on the market that caters for the smaller molecular structure of refrigeration gases, unlike fittings adapted from plumbing press fitting systems.

TriLock Press Profile

- The Streamline ACR Press Fitting system jaws have three distinct mechanical connection points that create superior joint strength and pressure handling capabilities than other systems on the market. The industry first, triple-crimp design also has an impressive structural integrity and pull-out strength and is aided by an extra deep cup design.

Force360 Press Contour

- Developed in partnership with hydraulic press tool leaders Novopress (manufacturers of the KemPress press tool), the FORCE360 PRESS CONTOUR uses a circular press design for the most uniform compression and sealing possible that out-performs hexagonal refrigeration press systems.

To learn more about the range of Streamline ACR Press Fittings range or our T.R.A.P Technology, visit our Streamline ACR Press Fittings product page.