Over the past 10-15 years, the introduction of copper press fittings into the Australian market has made a dramatic impact on the way we go about joining copper tube. With the installation process so easy, sometimes complacency can creep into work habits and in some cases, even forgetting to a press a fitting may occur that can lead to a leaking fitting. Sometimes the simplest solution is the best, and the KemPress system offers a simple solution that will leave you with a high quality leak free installation every time.

Some press system installations can require dozens if not hundreds of presses. Quickly and easily verifying that each press has been completed can be a concern and the last thing you want to be worrying about at the end of the job.

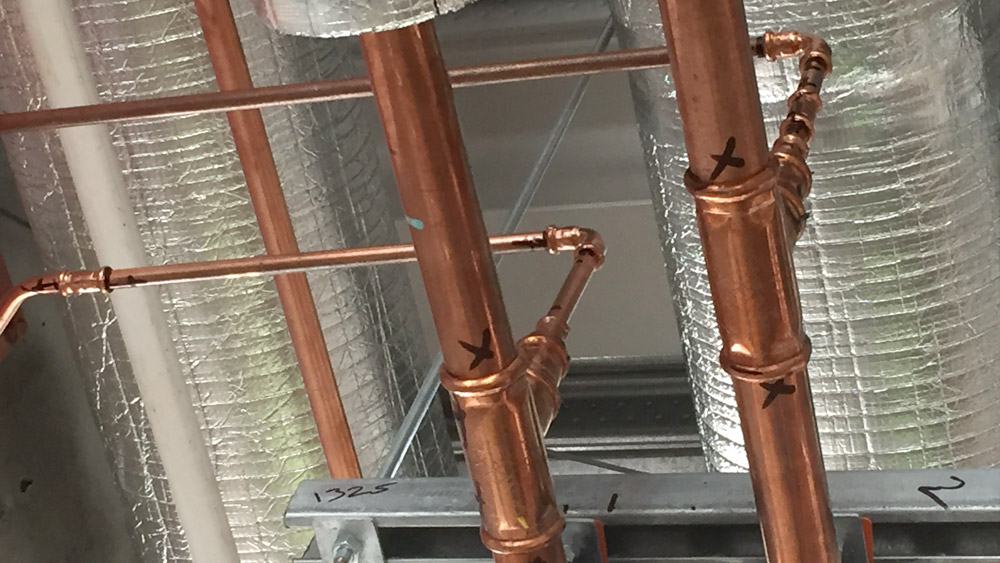

Whilst the pressing of a fitting itself will cause a visible deformation of the fitting, this can often not be obvious in low light areas or requires closely inspecting the pressed fitting. Many press systems on the market have attempted to solve this issue with leak paths or removable tags and whilst these are all potential solutions, they can lead to poor installation habits and practices. The best way to do something is to do it right the first time and often the simplest solution is the best. By simply marking each press on your KemPress fitting with a marker or spray you can easily identify unpressed fittings and audit installations visually all with your naked eye.

By using a marking spray or pen to indicate which KemPress fittings have been pressed as you press them it is easy to see, at a glance, which fittings in your job have been pressed and any that may have been missed. This method of marking the fittings as you go helps ensure that if a fitting is missed, it can be easily identified, saving you the tedious and time-consuming task of closely inspecting each join for a press deformation or relying on low pressure tests and leak path to identify an installation error after the event. This simple solution also encourages strong installation habits and processes across the job site, minimising installation risk for your projects.

It might seem simple, that’s because it is. Don’t mess about just press, mark and move on.