What makes Kembla Refrigeration & HVAC copper tube different from the rest? The copper tube making process is much more complex than one might imagine and studies show that some brands in the Australian market are taking this for granted and failing to conform to AS/NZ 1571. Kembla applies its 100 years of experience and stringent quality control systems to ensure every length of copper tube is manufactured to Australian Standards, never compromising on our promise of Quality, Relibility and Service. More.

Copper tube is renowned for its superior properties in HVAC and Refrigeration applications. Its exceptional corrosion resistance and durability make it perfectly suited for high-pressure applications, potentially outlasting the HVAC and refrigeration technology it is used with.

The copper tube-making process is much more complex than one might imagine, yet some brands of copper tube in the Australian market are taking this for granted. Their prices may seem low, but at what cost to quality? And at what cost to the customer?

Kembla understands that supplying consistent quality copper tube for HVAC & Refrigeration installations is imperative not only to the longevity of the installation, but the success and reputation of the designers and installers themselves.

With 100 years of experience in copper manufacturing and our stringent quality control systems, you can trust that the Kembla brand will never compromise on our promise of Quality, Reliability and Service.

KEMBLA QUALITY

We pride ourselves on meeting not only the Australian and New Zealand Standards but surpassing them with Kembla’s own in-house conformity specifications.

An extensive ISO 9001 certified quality system is applied to the manufacture of all Kembla tube, ensuring every length of copper tube is carefully made to Australian Standards.

Kembla strives for impeccable cleanliness of our HVAC & Refrigeration tube, with average test results being at least 75% cleaner than the requirements of AS/NZS 1571.

KEMBLA’S RELIABILITY

Kembla’s copper tube and fittings have a 25 year warranty and a commitment to quality standards beyond any other brand on the market.

Our in-house chemical composition analysis ensures that all Kembla tube conforms to the 99.90% minimum copper content standard, with every length of Kembla tube being traceable back to its time and place of manufacture.

Test certificates are readily available to our customers, so you have peace of mind that Kembla copper tube is of a premium standard, always.

Kembla’s reliability is further demonstrated via our renowned distribution network. Through state representation and convenient warehousing locations across Australia, Kembla continues to support our customers by providing our high quality copper products and service where and when you need them.

KEMBLA SERVICE

With Kembla’s promise of high quality products, it’s only fair to expect the same high quality from our second to none customer service team, based in Australia.

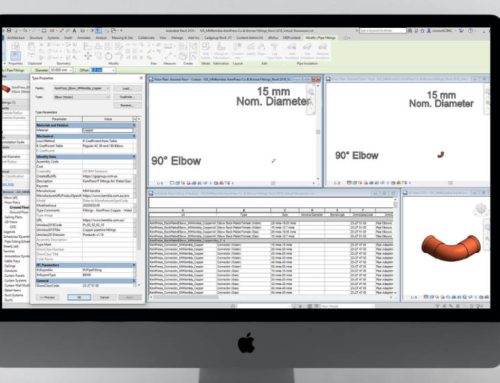

Kembla is the sole Australian supplier with onsite laboratory facilities for investigation, testing and analysis of copper tube.

Our technical and laboratory department is Australia’s leader in copper HVAC and Refrigeration product technical knowledge and can provide ongoing technical support services including:

- Assistance in HVAC & Refrigeration product selection.

- On-site visits and technical assistance.

- Testing, investigation and analysis of product or system failures, including installations using other brands of copper tube.

- Technical reporting on samples submitted for testing.

- Batch specific cleanliness certification of any single length of Kembla tube upon customers’ request.

‘COPPER TUBE AIN’T COPPER TUBE’

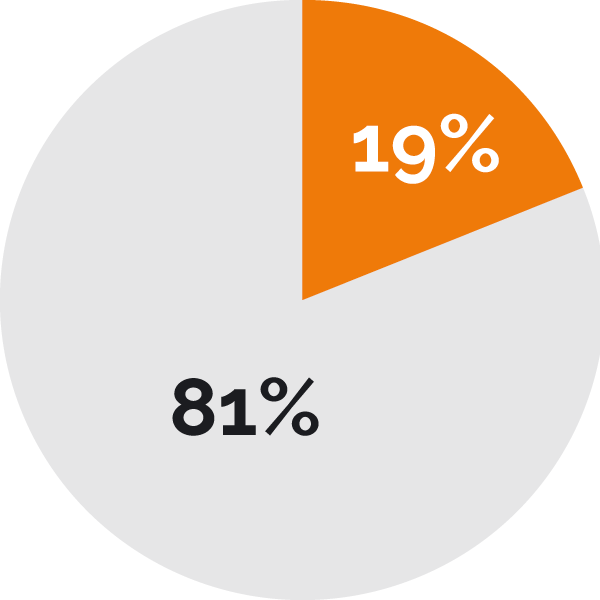

A study conducted by MM Kembla found that 81% of HVAC & Refrgeration copper tube sampled from the Australian market failed to meet the requirements of Australian Standards, exposing Australian installers, designers and merchants to increased risk and liability!

The Study

The Study

In July 2015, 60 samples of copper tube from 6 manufactures were randomly selected and tested for conformance to Australian and New Zealand Standards.

The Result

An alarming 81% of the Refrigeration and HVAC tube samples failed to meet Australian Standards.

What does this mean for Refrigeration and HVAC installers?

- Incorrect Wall Thickness

- Incorrect Outside Diameter

- Incorrect Hardness

- Cleanliness Failed

- Chemical Composition

- High Eccentricity