Australian Standard AS2896-1998 states;

Materials;

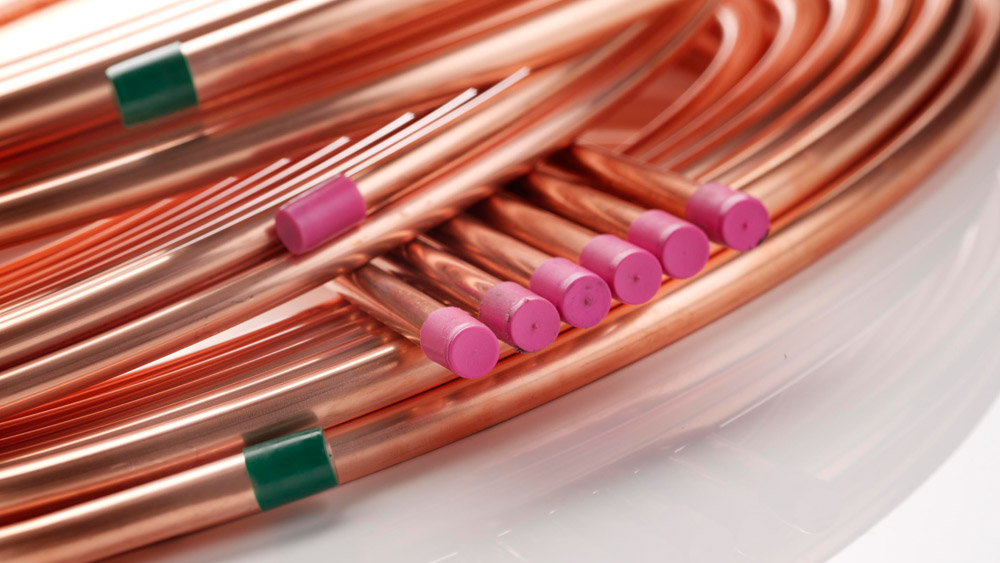

- Copper tube used in medical gas pipeline systems shall be of ‘as drawn’ seamless tube, manufactured in accordance with AS/NZS 1571.

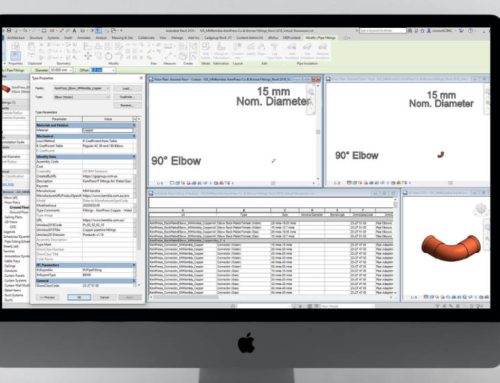

- Copper fittings shall be in accordance with ASME B 16.22.

- All components of the pipeline shall be compatible with oxygen, and shall be clean and free from oil, grease and particulate matter.

- Components include containers, pipes, lubricants, fittings, gaskets etc.

- Compatibility involves both combustibility and ease of ignition. Materials that burn in air will burn violently in pure oxygen.

Maintenance and cleaning of pipelines and components;

- MM Kembla Medical Gas tube, in accordance with AS/NZS 1571, is factory cleaned, degreased and capped prior to delivery. Tube shall not be cleaned on site, except for necessary purging operations to remove any particles entrained during installation.

- MM Kembla fittings are delivered clean, and are protected from contamination during delivery to the site.

- Particular care shall be exercised in the storage and handling of all Medical Gas tube and fittings.After cutting, tube shall be temporarily capped or plugged to prevent contamination before final assembly.Tools used in cutting or reaming shall be kept free from oil or grease.

- Cutting into an existing system should be carried out with a radial pipe cutter, which does not produce cuttings or filings.

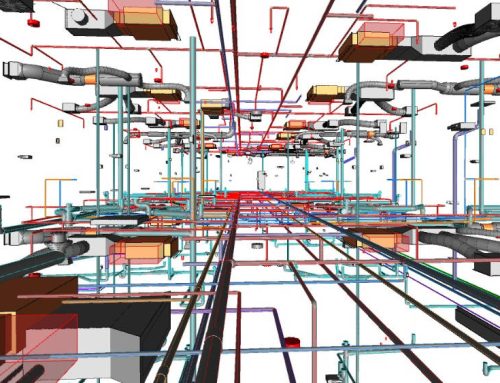

Design requirements for Medical Gas pipelines

- Pipelines and fitting sizes shall be selected to provide the required design flow of the entire health care facility.

- The nominal design working pressure shall be 415 kPa for medical gas supply, -60 kPa for medical suction, and 1400 kPa for surgical tool gas supply.

- Flow requirements should be determined on the basis of discussions with the health care facility to ascertain the expected and projected gas usage and number of terminal units required.

- The design, fabrication, installation and inspection of all Medical Gas pipeline systems should comply with AS 4041.

Protection of pipelines;

- Pipelines in exposed areas shall be protected from physical damage.

- Buried pipelines shall be protected adequately against frost, corrosion and physical damage.

- Copper tubes may experience severe corrosion if buried in direct contact with certain aggressive environments.

- MM Kembla Kemlag sheaths are available to fit over and protect 12.##7mm (1/2”) and 19.##05 (3/4”) size copper tube.

- Medical gas pipelines may be placed in the same tunnel, trench or duct with fuel gas pipelines or steam lines, provided that these medical gas pipelines are a minimum of 50mm from other services and provided there is good ventilation.

- Medical gas pipelines shall not;

- Be placed in a tunnel where contact with oil could occur.

- Be installed in or through any air duct, clothes chute, lift well, rubbish chute or ventilation duct.

- It is not recommended that Medical Gas pipelines be cast into reinforced concrete or installed under slab on ground floors.

- Where pipelines pass through masonry walls, partitions or floors, the pipeline should be fitted with protective sleeves. ie. MM Kembla Kemlag sheaths.

Fluxless Brazing Technique

- All joints (copper tube and fittings) shall be brazed.

- All brazing alloys used in the fabrication of pipes and fittings shall comply with B4 alloy designation as specified in AS 1167.1

- Flux shall not be used on-site. For off-site applications, only water-based flux shall be used.

- During brazing operations, commercial-grade carbon dioxide shall be used as an internal inert gas shield.

The fluxless technique with an inert atmosphere, prevents contamination of the inside of the pipe with flux residues and oxide scale, and minimizes the fire risk of brazing.

Upon completion, the work needs to be purged and tested for particulate matter and for carbon dioxide.

REFERENCES

- Australian Standard AS2896-1998. Medical gas systems – Installation and testing of non-flammable medical gas pipeline systems.